Erection Process:

1. Design

- Design of architectural drawings: presentation of design solutions, analysis and evaluation and consulting the best price options for the needs of the investor. Then, complete the design of architecture, structure, materials and express intent on the perspective drawings, vertical, plan, cross section.

- Design of the work drawing: Once the architectural drawing is approved, the work drawing will detail and clearly code the structure on the drawing. Wrong expressions will lead to extremely serious mistakes affecting the quality of the works.

2. Processing

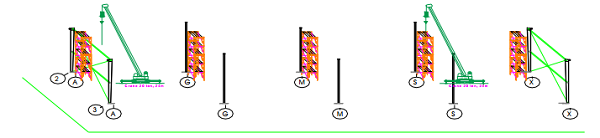

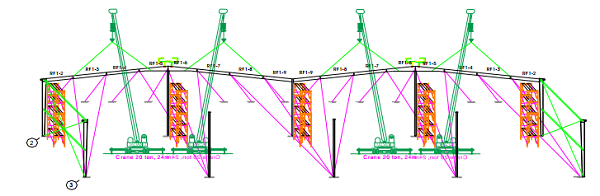

3. Installation

Request:

Engineers must read the detailed layout of each component and the installation order in the installation drawing to ensure the quality and safety of the works. This stage is carried out with the help of crane to bring the components up.

Key stages in the erection process:

- Survey, inspection, planning for the preparation, equipment, delivery and storage of materials at the site.

- Plan for monitoring, checking and urging.

- Install the lock boom.

- Installation of beam girder.

- Installation of rafters, purlins, anti-purlin, rafters.

- Roofing and roofing.

- Installation of wall purlins, walls, gutters, drain pipes.

- Other doors and fittings.

- Conduct quality inspection and evaluation

Advantages of prefabricated houses

- Light weight compared to reinforced concrete greatly reduces the load pressure.

- Saving more raw materials than the construction of other types of houses.

- The large prefabricated home , which helps to operate in it throughout and united.

- High synchronization, easy to expand the scale when the business grow.

- The cost of this type of house is also much more economical than other types due to short time of construction, low cost of warranty, significant reduction of labor cost at site, simple materials without frills. Especially with less force-bearing areas, pre-fabricated houses show the better of these advantages.

- The durability of prefabricated house can be from 70 years to 100 years .

- Fast, simple design, fabrication and erection in spite of weather conditions . Normally, it takes up to 90 days for a traditional home construction to take 6 months. This is very economical when the works are put into use and exploited quickly.

Design standards

INTERNATIONAL STANDARD

- AWS D1.1 Edition 2006

- AISC. 2005 - American Institute of Steel Constructions

- MBMA. 2002 - Metal Building System Manu

- Quality Manual

VIETNAM STANDARD

- TCXD VN 338: 2005. Steel structure - Design standards.

- TCVN 3223: 1994. Welding electrodes for carbon steel and low alloy steel;

- TCVN 1916: 1995. Bolts, screws, screws and nuts. Technical requirements;

LABORATORY TESTING

- TPI Third Party Inspection

- NDT non-destructive Testing

- Magnetic Particle Inspection MPI

HOTLINE: 0988 55 88 79 - 0903 831 312

HOTLINE: 0988 55 88 79 - 0903 831 312